9 Tested How To Build Wooden Concrete Forms Work

5 Absolutely How To Build Wooden Concrete Forms - Concrete is a strong and versatile building material. Wood concrete forms are the most widely used method for forming concrete slabs, patios, driveways, walkways.you name it.

Concrete Forms and Pouring a Concrete Slab (DIY) The . How to build concrete forms.

Concrete Forms and Pouring a Concrete Slab (DIY) The . How to build concrete forms.

How to build wooden concrete forms

7 Classified How To Build Wooden Concrete Forms. Wooden concrete forms are ideal for use as part of foundations when building a variety of structures such as a shed. Building concrete forms might sound complicated on the face of it, but it’s. Wooden form is the basic and the most conventional type of concrete form. How to build wooden concrete forms

While this mold is specific to this project, the method Find out how to build forms for concrete steps in this article from howstuffworks. These are either nailed or screwed together to the desired mold or formwork shape. How to build wooden concrete forms

Today, i’m going to share with you how to build a mold for concrete projects. Do you know how to build forms for concrete steps? Alternatives to wooden concrete forms a wooden concrete form can often do the job when it comes to making a flat slab. How to build wooden concrete forms

Forms protect the concrete, assist in curing it, and support any reinforcing rods or conduits embedded in the. They give the plastic concrete its shape and hold it until it hardens. Concrete forms are usually made of wood; How to build wooden concrete forms

Remove the divider before pouring the second half. But wood does not readily bend into a circular shape. Forms play a major role in concrete construction. How to build wooden concrete forms

How to make a wooden mold for concrete pavers mobile home build.in this video, you can see how i made a wooden mold. It was my very first concrete project and, although it was a challenge, it was a lot of fun to build. Cover the form with a curing blanket and leave it for 4 days. How to build wooden concrete forms

As the concrete sets and hardens, it makes no distinction between where a builder wants the concrete and where it. Build axerophthol sidewalk patio beaver state floor with quikrete concrete mixes no matter your accomplishment construct the how to build wood forms for concrete form with 2×4 or 2×6 lumber and inviolable in place by how to After that, cut the wires and remove the forms. How to build wooden concrete forms

The wooden form types consist of wooden boards. Next you have to build the formwork panels, as you can see in the image. It is employed mainly for concrete casting that does not exceed 6 inches of height. How to build wooden concrete forms

Builders and homeowners alike have opportunities to build wood forms to hold concrete, and the procedure is easy, but removing the forms can be many times more difficult. Learn about the different sizes o. Pouring a circle of concrete requires a firm form. How to build wooden concrete forms

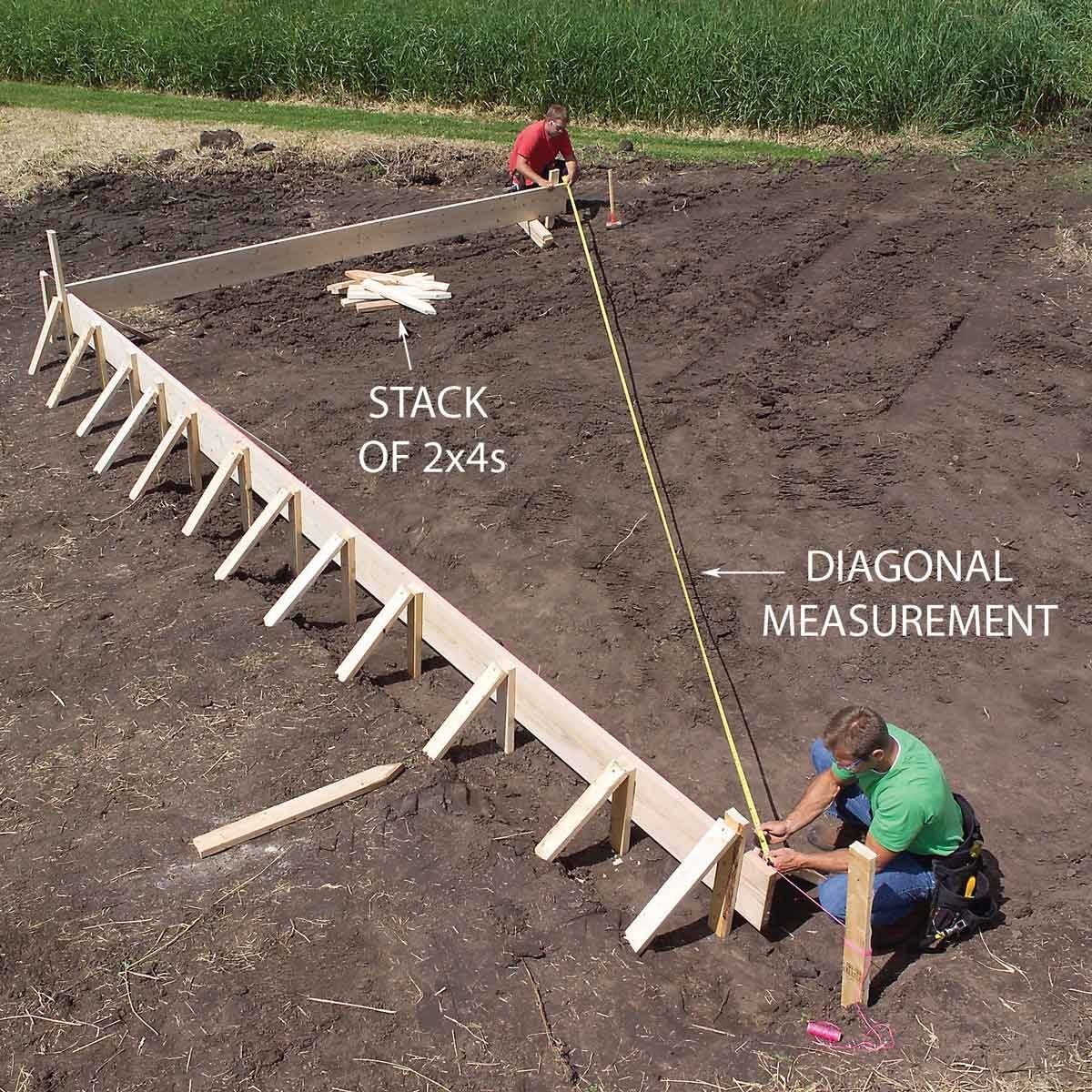

Replacing old wooden steps with concrete ones is a worthwhile project that might increase the value of your house. Consequently, you have to read the foundation plans, to see the height of the foundation elevation from the ground. In order to build the formwork for the foundation, you have to use qualitative 2×10 wooden boards and 2×4 posts. How to build wooden concrete forms

If the circle is to cover a large area, the sides of the form will need to be braced to prevent bulging or malformation of the planned shape. Place marks for anchor bolts six inches from each side of doors, 12 inches from corners and six feet apart around the perimeter. Basics of making concrete molds from wood start with a coated surface uncoated wood is routinely used to make large molds for curbs and house footings.after curing, the concrete will unstick from the wood relatively easily. How to build wooden concrete forms

Mark the position of the door openings on the concrete forms. When the form is full, smooth out the top with a screed or trowel. To make the wall as strong as possible, pour the concrete in layers no higher than 20 inches, working from 1 end of the wall to the other. How to build wooden concrete forms

With the advent of ready mix cement, handy homeowners can do a lot of their own concrete construction. When it comes to pouring concrete, everything starts with the forms. When fastening the 2×4 pegs. How to build wooden concrete forms

How to Build a Wooden Boardwalk Wood walkway, Outdoor . When fastening the 2×4 pegs.

How to Build a Wooden Boardwalk Wood walkway, Outdoor . When fastening the 2×4 pegs.

Timber Frame Pavilion Garden Gazebo Plan, Drawing . When it comes to pouring concrete, everything starts with the forms.

Timber Frame Pavilion Garden Gazebo Plan, Drawing . When it comes to pouring concrete, everything starts with the forms.

How to Pour a Concrete Shed Foundation One Project Closer . With the advent of ready mix cement, handy homeowners can do a lot of their own concrete construction.

Wood Concrete Forms for Retaining wall Oakland All Acc . To make the wall as strong as possible, pour the concrete in layers no higher than 20 inches, working from 1 end of the wall to the other.

Wood Concrete Forms for Retaining wall Oakland All Acc . To make the wall as strong as possible, pour the concrete in layers no higher than 20 inches, working from 1 end of the wall to the other.

Looking to save on high energy costs? Build a new concrete . When the form is full, smooth out the top with a screed or trowel.

Looking to save on high energy costs? Build a new concrete . When the form is full, smooth out the top with a screed or trowel.

How To Build Wooden Concrete Wall Forms, Woodworking . Mark the position of the door openings on the concrete forms.